Pickering, ON Canada

+1-416-342-7547

+1-647-669-5430

sales@atwoodsales.com

http://www.atwoodsales.com

Mobile Glass Handling Solutions

Glass Storage, Dollies, Other

CNC Glass Cutting Tables

Glass Fabrication Machines

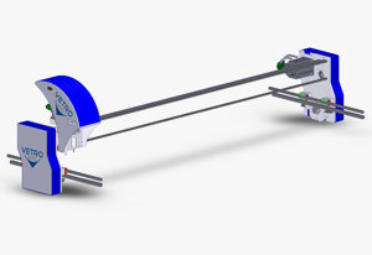

Quick Change

Wheel System

INNOVATIVE DESIGN

A totally innovative design approach reclassifies the state of the art

industry, enabling the creation of modular machines made up totally of

components employing CAD-CAM technology. The VETROMAC Team

controls all the construction phases directly; concept design, 3D design,

mechanical machining of individual details by CNC machining centres,

assembling and testing of machines, are all totally in-house processes.

All this with obvious advantages:

Strict quality control.

Absolute uniformity and repeatability with the possibility of interchanging

any component (including the cloth panel) without any need for any

adjustments.

Cutting speed and precision never seen before; similar and sometimes

even higher than expensive machines with linear motors.

Very low wear due to a mechanically perfect construction.

Possibility to upgrade machines previously built with the addition of the

latest developments, up to the possibility of changing the size of the

machine itself.

Welcome to cncGlassCuttingMachines.com

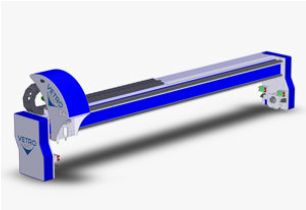

SLIDING SYSTEM

The sliding system of the bridge are made with a pinion-rack system. The racks and

the pinions are tempered and refaced. They have a ± 0.02 mm tolerance with 1.20 MT

(47.24 in) length. The teeth om the racks are turned towards low. One pinion is placed

on the two sides of the bridge, to keep always perpendicular the bridge to the cutting

table during the acceleration and deceleration phases.

On both sides of the table is applied one linear guide and one rack, to obtain a overall

bridge stability during the cutting cycle.

NORTH AMERICAN SUPPORT

Atwood Sales is the agent for Vetromac in Canada and USA. We have a Vetromac partner

technician based out of Chicago and store parts in our office near Toronto . Designed to

require minimal service, our technician is often available to help with real time issues.

ITALIAN QUALITY

AT AN AFFORDABLE PRICE

An excellent project needs skill and passion to achieve

perfection. The “100% made in Italy” construction of the

VETROMAC machines is the feather in the hat that ensures that

each single machine is assembled with passion and ability to

reach a working life of over twenty years as per Italian tradition.

Every single machine component is chosen with the utmost care

from the best suppliers on the market - all this at a very

competitive price.

CUTTING HEAD

Well designed low friction piston cutting head with edge safety system that is durable

and will give years of trouble-free glass cutting.

Pickering, ON Canada

+1-416-342-7547

+1-647-669-5430

sales@atwoodsales.com

http://www.atwoodsales.com

Mobile Glass Handling Solutions

Glass Storage, Dollies, Other

CNC Glass Cutting Tables

Glass Fabrication Machines

Quick Change

Wheel System

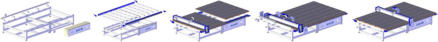

CONCEPT OF

PRODUCTION AND

ASSEMBLY

We have developed a new concept of

building machines, every single part of

the machine is designed with 3D CAD

technology, processed by CAD CAM

and machined with a CNC Working

Center.This innovative system is the

only one that can guarantee perfect

uniformity and constant quality of all

the machines that are being built and

every single part of the machine can

be easy replaced if needed, even the

felt table surface.The machines

assembly is divided into specific steps,

controlled by a management software,

which supports and guides our

technicians during the various stages

of assembly, the following pictures is

an example of the assembly steps:

INNOVATIVE DESIGN

A totally innovative design approach

reclassifies the state of the art

industry, enabling the creation of

modular machines made up totally of

components employing CAD-CAM

technology. The VETROMAC Team

controls all the construction phases

directly; concept design, 3D design,

mechanical machining of individual

details by CNC machining centres,

assembling and testing of machines,

are all totally in-house processes.

All this with obvious advantages:

Strict quality control.

Absolute uniformity and repeatability

with the possibility of interchanging

any component (including the cloth

panel) without any need for any

adjustments.

Cutting speed and precision never

seen before; similar and sometimes

even higher than expensive machines

with linear motors.

Very low wear due to a mechanically

perfect construction.

Possibility to upgrade machines

previously built with the addition of

the latest developments, up to the

possibility of changing the size of the

machine itself.

EXTENDED

WARRANTY

Total control of the “in-house”

production phasees and the

computerised precision obtained with

all the CNC machining operations,

result in a durability and reliability that

allow us to grant warranty beyond

industry norms. 4 years or 10,000

working hours, whichever comes first.

EXCELLENT AFTER-

SALES SERVICE

The intrinsic quality of our machines

reduces the demand for assistance,

thus reducing the machine stops and

the need for post-sales assistance.

This results in our technicians being

more readily available to assist you.

Remote software connectivity allow

them to connect from wherever they

are in real time.

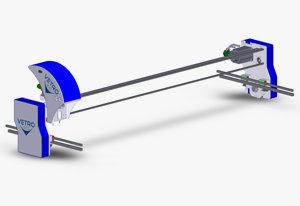

SLIDING SYSTEM

The sliding system of the bridge are

made with a pinion-rack system. The

racks and the pinions are tempered and

refaced. They have a ± 0.02 mm

tolerance with 1.20 MT (47.24 in) length.

The teeth om the racks are turned

towards low. One pinion is placed on

the two sides of the bridge, to keep

always perpendicular the bridge to the

cutting table during the acceleration

and deceleration phases.

On both sides of the table is applied

one linear guide and one rack, to obtain

a overall bridge stability during the

cutting cycle.

CUTTING BRIDGE

The cutting bridge is made in rigid

steel. The whole system is very stable

and insensitive to temperature

changes, assuring minimum wear and

tear.

The cut trolley is made in aluminum.

The cutting head is made with special

machines with hundredth tolerances.

The up and down system of the cutting

head is guided by a system with re-

circulation of ball-bearings, to reduce

the friction as much as possible and

guarantee the cutting head response

to glass scoring.

CUTTING PRESSURE

SYSTEM

The cutting head is equipped with a

unique dual management system for

cutting pressure. If the automatic

proportional valve doesn’t work

properly, it is possible to switch to

manual mode simply by rotating the

appropriate switch, from Auto to

Manual and continue cutting.

ITALIAN QUALITY

& AFFORDABLE

An excellent project

needs skill and passion

to achieve perfection.

The “100% made in Italy” construction

of the VETROMAC machines is the

feather in the hat that ensures that

each single machine is assembled

with passion and ability to reach a

working life of over twenty years as

per Italian tradition. Every single

machine component is chosen with

the utmost care from the best

suppliers on the market -- all this at a

very competitive price.

NORTH-AMERICAN

SUPPORT

Atwood Sales is the

agent for Vetromac

in Canada and USA.

We have a Vetromac

partner technician based out of

Chicago and store parts in our office

near Toronto. Designed to require

minimal service intervention, our

technicians are often available to

help with real time issues.